Increasing airflow and RPM might seem like quick ways to boost engine performance, but faster isn’t always better. Pushing these limits can cause turbulence, increased wear, and overheating, which may lead to engine damage or decreased efficiency. Proper balance is essential—more speed without control can do more harm than good. If you want to understand how to optimize performance safely, there’s more to uncover about managing airflow and RPM effectively.

Key Takeaways

- Increasing RPM boosts airflow but can cause turbulence, noise, and mechanical stress, reducing overall efficiency and component lifespan.

- Excessive airflow at high RPM may lead to backpressure, overheating, and turbocharger stress, risking system failure.

- Faster RPM doesn’t always improve cooling; beyond optimal points, it can cause instability and reduced performance.

- Balancing airflow and RPM prevents over-revving, minimizing wear, noise, and fuel consumption issues.

- Proper monitoring and tuning help optimize airflow-RPM relationship, avoiding the pitfalls of over-optimization.

ZMISHIBO 72 inch Large Ceiling Fans with Lights and Remote, Indoor/Outdoor Black Modern Ceiling Fan for Kitchen Living Room Patio, 6 Speed Reversible Quiet DC Motor, 3 CCT, Dual Finish 8 Blades

72 Inch Ceiling Fan: This large ceiling fan includes 4“, 8”, and 24“ down rods, making it a...

As an affiliate, we earn on qualifying purchases.

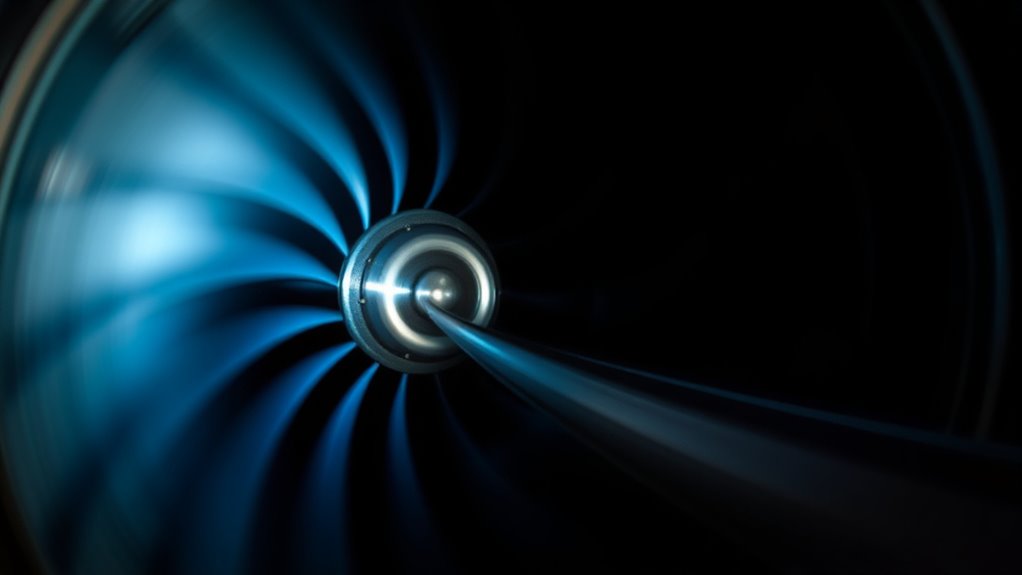

Understanding Airflow and RPM Basics

To understand how airflow and RPM influence cooling performance, it’s essential to grasp their basic principles. Airflow involves the movement of air or coolant through a system, directly affecting how heat is carried away. Higher airflow increases coolant flow, which helps remove heat more efficiently. RPM, or revolutions per minute, determines how quickly components spin, affecting the exhaust velocity — the speed at which hot gases exit the system. Faster RPMs can boost airflow but don’t always translate to better cooling if airflow becomes turbulent or inefficient. The key is balancing airflow and RPM to optimize coolant flow and exhaust velocity, ensuring heat is effectively carried away without causing unnecessary noise or energy consumption. Additionally, airflow distribution within a system plays a crucial role in preventing hotspots and maintaining overall cooling efficiency. Proper airflow management can prevent bottlenecks and ensure uniform heat dissipation across all components.

LEVOIT Air Purifiers for Home Large Room Up to 1875 Ft² with Washable Pre-Filter, AHAM VERIFIDE, Air Quality Monitor, HEPA Sleep Mode for Allergies, Pet Hair in Bedroom, Vital 200S-P, White

𝐖𝐇𝐘 𝐂𝐇𝐎𝐎𝐒𝐄 𝐀𝐇𝐀𝐌 𝐕𝐄𝐑𝐈𝐅𝐈𝐃𝐄 𝐏𝐑𝐎𝐃𝐔𝐂𝐓𝐒: AHAM (Association of Home Appliance Manufacturers) is an ANSI-accredited organization that sets strict...

As an affiliate, we earn on qualifying purchases.

The Relationship Between Airflow and RPM

Airflow and RPM are closely interconnected when it comes to cooling performance. As RPM increases, the engine demands more airflow to prevent overheating and maintain efficiency. Turbo charging benefits from higher RPMs because it compresses more air, boosting power without sacrificing temperature control. Fuel injection systems rely on ideal airflow to deliver precise fuel amounts, which helps avoid engine knocking or overheating. When RPM rises, airflow must keep pace to support combustion and cooling needs. Additionally, AI’s ability to optimize engine performance and adapt to real-time conditions can help balance airflow and RPM for enhanced reliability. Excessive RPM without proper airflow can lead to overheating or damage, which underscores the importance of monitoring cybersecurity vulnerabilities that could impact engine management systems.

LEVOIT Air Purifier for Home Allergens Pet Hair in Bedroom, Covers Up to 1073 ft² by 56W High Torque Motor, AHAM VERIFIDE, 3-in-1 Filter with HEPA Sleep Mode, Remove Dust Smoke Odor, Core300-P, White

WHY CHOOSE AHAM VERIFIDE AIR PURIFIERS: AHAM (Association of Home Appliance Manufacturers) is an ANSI-accredited organization that sets...

As an affiliate, we earn on qualifying purchases.

When Increased Speed Becomes Counterproductive

As you push an engine to higher speeds, there comes a point where increasing RPM and airflow no longer improve performance and can even cause harm. Beyond certain speed limits, your tuning adjustments might become counterproductive, leading to instability or mechanical stress. Over-optimizing airflow or revving past recommended limits can strain engine components, reduce efficiency, and shorten lifespan. Instead of chasing higher numbers, focus on fine-tuning your setup within safe parameters. Recognizing when additional RPM no longer adds power helps prevent damage and preserves reliability. Proper ventilation and airflow in engine design can optimize performance without risking damage. Remember, faster isn’t always better—sometimes, maintaining a balanced airflow and respecting speed limits yields better performance and longevity. Pushing beyond these limits isn’t just unnecessary; it can be detrimental. Additionally, understanding engine tuning principles can help you achieve optimal performance while maintaining engine health. Proper suspension upgrades can further enhance handling, allowing you to maintain control at safe speeds.

KNKA Air Purifier for Home Bedroom Large Room, HEPA Air Cleaner with Washable Pre-Filter, AQI Display, ECO Mode, Sleep Mode, Pet Mode for Pets, Dust, Pollen, APH4000, White

𝐇𝐢𝐠𝐡 𝐂𝐀𝐃𝐑 𝐕𝐚𝐥𝐮𝐞: This air purifier provides reliable performance with a Smoke/Dust/PM2.5 CADR of 226 CFM (384 m³/h)...

As an affiliate, we earn on qualifying purchases.

The Risks of Over-Revving and Excessive Airflow

Pushing your engine beyond its limits can cause serious damage and lead to costly repairs. Over-revving and excessive airflow waste fuel and can substantially decrease your vehicle’s efficiency. Plus, you’ll notice increased noise levels that can make driving less comfortable and more noticeable to others. Understanding the airless technology and how it impacts performance can also help in maintaining optimal engine function. Additionally, improper airflow management can disrupt the delicate balance of engine components, leading to uneven wear and potential mechanical failure.

Engine Damage Risks

Excessive airflow and over-revving can considerably increase the risk of engine damage, especially if you ignore the engine’s limits. Pushing your engine beyond its designed RPM can strain components, leading to premature wear or failure. Turbocharging effects, while enhancing power, can cause the engine to operate under higher stress, increasing the risk of damage. Additionally, excessive airflow can disrupt exhaust flow, causing backpressure and overheating. Proper airflow management is essential to prevent these issues and maintain engine health. – Damaged pistons and valves from over-revving – Turbocharger failure due to excessive boost pressures – Increased wear on bearings and crankshaft – Exhaust system stress, leading to leaks or cracks. Ignoring these risks can result in costly repairs and reduced engine lifespan. Maintaining suitable airflow and respecting RPM limits helps protect your engine’s integrity and ensures reliable performance.

Fuel Efficiency Loss

When you operate your engine beyond its recommended RPM or allow excessive airflow, you not only risk damage but also undermine fuel efficiency. Over-revving forces the engine to work harder, burning more fuel than necessary, which directly impacts your fuel savings. Excessive airflow can cause the engine to run lean or rich, disrupting ideal combustion and leading to higher fuel consumption. This inefficient operation also results in increased emissions, making it harder to achieve emissions reduction goals. Pushing your engine beyond its ideal limits wastes fuel and creates unnecessary strain on components. To maximize fuel savings and support environmental efforts, stick to manufacturer-recommended RPMs and airflow levels, ensuring your engine runs smoothly and efficiently without sacrificing performance or damaging its parts. Additionally, understanding the role of engine calibration can help optimize airflow and RPM settings for better efficiency, ultimately fostering a growth mindset toward vehicle maintenance and eco-friendly driving practices.

Increased Noise Levels

Over-revving your engine or allowing too much airflow can considerably increase noise levels, making your vehicle much louder than necessary. This heightened airflow noise often coincides with increased rpm vibration, causing your car to emit a constant droning sound. Excessive airflow can also amplify engine whine and mechanical rattle, leading to discomfort during drives. When you push beyond ideal limits, you risk not only noise pollution but potential damage to engine components. Understanding the refrigeration cycle can help prevent issues related to airflow and engine stress, just as understanding the horsepower of electric dirt bikes can inform proper performance limits. Additionally, managing airflow appropriately is essential for maintaining engine efficiency and avoiding unnecessary strain.

Identifying the Optimal Balance for Efficiency

Finding the right balance between airflow and RPM is essential for maximizing engine efficiency. Focus on airflow optimization by ensuring your system delivers sufficient air without causing excessive turbulence or noise. Proper rpm control helps maintain this balance, preventing the engine from running too fast or too slow for optimal performance. Too high RPMs can lead to wasted energy and increased wear, while too low may cause insufficient airflow, reducing power. To identify the ideal point, monitor engine response and adjust airflow and RPM settings accordingly. Aim for a harmonious relationship where airflow meets demand without overtaxing the engine. This balance minimizes energy loss, extends component lifespan, and boosts overall efficiency, making your engine run smoother and more reliably. Regular check-ups and understanding the impact of engine performance factors can further enhance this balance. Recognizing the influence of dog breed characteristics can also help tailor maintenance and operation for specific engine types or applications. Additionally, keeping an eye on AI safety measures and related developments can inform best practices for incorporating advanced technology into engine management systems.

Case Studies: Performance Gains vs. Damage

Case studies reveal that optimizing airflow and RPM can substantially boost performance, but pushing these parameters too far often causes engine damage. Excessive airflow can strain turbochargers, reducing their efficiency and risking overheating. High RPM levels generate more heat, impacting the cooling system’s ability to maintain ideal temperatures. For example, one case showed that increasing airflow improved power output, but over-boosting led to turbocharger failure. Similarly, pushing RPM beyond recommended limits caused overheating and component wear. Proper management of airflow and RPM is essential to maximize gains while minimizing the risk of damage. Mismanagement of these factors can also lead to emotional stress on the engine components, increasing the likelihood of failure. Damage often outweighs performance gains when airflow and RPM are mismanaged

Tools and Techniques for Monitoring Airflow and RPM

To keep an eye on airflow and RPM, you’ll want to use tools like anemometers and digital tachometers. These devices provide real-time data that help you understand how your system performs. Additionally, analyzing trends with specialized software can reveal patterns and guide your maintenance decisions.

Using Anemometers Effectively

Using anemometers effectively requires understanding how to select the right tool and apply proper measurement techniques. To get accurate airflow measurement, choose an anemometer suited for your environment—consider vane, hot-wire, or ultrasonic types. Properly positioning the device guarantees consistent readings, avoiding turbulence or obstructions. Regular rpm calibration helps maintain measurement accuracy, especially when monitoring airflow related to fan speed. Keep these tips in mind:

- Use the correct anemometer type for your airflow conditions

- Maintain consistent distance and orientation during measurements

- Calibrate your device regularly to ensure accuracy

- Record data systematically for comparison and troubleshooting

Mastering these techniques ensures reliable airflow measurement, improves system efficiency, and helps you interpret airflow versus RPM relationships more effectively.

Digital Tachometers and Data

Have you considered how digital tachometers can streamline your airflow and RPM monitoring processes? These tools provide precise airflow measurement and simplify rpm calibration, guaranteeing accurate data collection. Digital tachometers quickly capture real-time readings, reducing manual errors and saving time. They often feature easy-to-read displays and data logging capabilities, making it simple to track trends over time. This accuracy helps maximize airflow systems and prevent over- or under-performance. Here’s a quick comparison:

| Feature | Benefit |

|---|---|

| Airflow measurement | Ensures system efficiency and safety |

| RPM calibration | Maintains accurate rotational speed |

| Data logging | Enables trend analysis and troubleshooting |

With digital tachometers, you gain reliable data that enhances your ability to fine-tune airflow and RPM for superior performance.

Analyzing Trends With Software

Analyzing trends with software transforms raw airflow and RPM data into actionable insights. By visualizing data over time, you can detect patterns like thermal expansion effects or changes in lubrication viscosity that impact performance. Software tools allow you to monitor airflow fluctuations and RPM variations precisely, helping you predict when equipment might require maintenance. Techniques such as real-time dashboards and historical analytics identify subtle shifts that could lead to overheating or increased wear. You can also set alerts for critical thresholds to prevent failures. Additionally, analyzing data helps optimize airflow rates without sacrificing efficiency, ensuring RPMs are balanced with thermal and lubrication factors. This approach keeps your system reliable, saving you from costly downtime and extending equipment lifespan.

Strategies for Achieving Peak Performance Safely

Achieving peak airflow and RPM without risking damage requires a strategic approach. To do this safely, start by addressing turbo lag, which can limit responsiveness at high speeds. Optimizing turbo spool through proper tuning guarantees smoother power delivery without stressing components. Next, focus on precise fuel mapping; fine-tuning your fuel mixture guarantees efficient combustion, preventing issues like knocking or overheating. Avoid pushing your engine beyond its limits by incrementally increasing airflow and RPM, monitoring performance closely at each step. Use diagnostic tools to track pressure, temperature, and fuel data, making adjustments as needed. Remember, consistent testing and gradual upgrades help you reach peak performance without compromising engine longevity, ensuring you stay safe while maximizing airflow and RPM.

Common Myths About Speed and Efficiency

Many common beliefs about boosting speed and efficiency can be misleading, leading you to make unnecessary or even harmful modifications. These speed myths and efficiency misconceptions often cause frustration. For example, thinking that increasing RPM always improves performance ignores airflow and cooling needs. Similarly, believing that bigger fans or higher speeds automatically mean better airflow can be false. You might also assume that reducing airflow reduces noise without affecting cooling, which isn’t always true. Finally, some think that the fastest speeds mean the best efficiency, but this isn’t accurate. To optimize performance, focus on balanced airflow and RPM instead of chasing speed myths. Recognizing these misconceptions helps prevent costly mistakes and enhances your understanding of real efficiency.

Frequently Asked Questions

How Does Ambient Temperature Affect Airflow and RPM Efficiency?

Ambient temperature impacts airflow and RPM efficiency because higher ambient heat reduces the cooling capacity of airflow. When it’s hot, your system struggles with airflow cooling, causing components to overheat and RPMs to slow down to prevent damage. Cooler temperatures improve airflow, helping maintain ideal RPMs. So, in warmer environments, expect decreased efficiency as the system works harder to cool itself, highlighting the importance of proper ventilation and cooling solutions.

Can Modifying Airflow or RPM Void Vehicle Warranties?

Thinking about tweaking your vehicle’s airflow or RPM might seem tempting, but it’s wise to take into account the potential warranty implications. Such modifications can sometimes be viewed as alteration risks, possibly voiding your warranty if issues arise. While improvements can boost performance, always weigh the benefits against the possible consequences. Staying within manufacturer guidelines ensures you enjoy your vehicle’s full benefits without unknowingly risking future coverage or facing unexpected repair costs.

Are There Industry Standards for Safe Airflow and RPM Levels?

You should know that industry standards for safe airflow measurement and rpm regulation exist to prevent damage and maintain vehicle safety. Manufacturers set these guidelines based on testing, so exceeding them can lead to warranty issues or mechanical failures. Always check your vehicle’s manual or consult professionals to guarantee your modifications stay within recommended airflow and rpm levels, helping you avoid potential risks and keep your vehicle running smoothly.

How Does Airflow Impact Fuel Efficiency in Engines?

Think of your engine’s air intake as a steady breeze fueling a fire. When airflow hits the sweet spot, it boosts combustion efficiency, making your engine run smoothly and saving fuel. Too little airflow starves the engine, while too much causes turbulence, wasting energy. Proper airflow ensures your engine breathes just right, enhancing fuel use and keeping it humming along efficiently. Balance is key for ideal performance and fuel savings.

What Role Does Vehicle Aerodynamics Play in Airflow Optimization?

Vehicle aerodynamics play a vital role in airflow optimization by reducing vehicle drag through aerodynamic design. When you focus on streamlining your vehicle’s shape, you minimize air resistance, which helps improve fuel efficiency and performance. By managing airflow around your vehicle, you decrease drag forces that slow you down, making your drive smoother and more fuel-efficient. Good aerodynamic design guarantees ideal airflow, enhancing overall vehicle efficiency and driving experience.

Conclusion

Remember, more airflow and higher RPM don’t always mean better performance. In fact, exceeding ideal levels can reduce efficiency by up to 30%, risking damage and costly repairs. By monitoring your system closely and finding that sweet spot, you guarantee peak performance without unnecessary wear. Stay informed with the right tools and techniques, so you can enjoy faster speeds safely—and keep your equipment running smoothly for the long haul.