Many believe all DC motors are inherently noisy, but the reality depends on design, how you operate them, and maintenance. Vibration, misalignment, wear, and electrical issues can increase noise levels, while good construction, proper mounting, lubrication, and insulation can keep motors quiet. Factors like load, speed, and temperature also play roles. If you’d like to learn how to identify and reduce noise effectively, there’s more to discover below.

Key Takeaways

- Many believe all DC motors are inherently noisy; actual noise levels depend on design, construction, and operating conditions.

- Mechanical issues like imbalance or misalignment significantly increase noise, but proper maintenance can reduce it.

- Noise reduction techniques such as damping materials and acoustic insulation effectively minimize motor sound emissions.

- Higher speeds and load variations can amplify noise, but optimized design and cooling help control these effects.

- Accurate measurement and diagnostics differentiate between myths and real causes of DC motor noise.

Common Perceptions About DC Motor Noise

Many people believe that DC motors are inherently noisy because of their mechanical components and electrical operations. However, this perception often overlooks how effective vibration damping can reduce the transmission of vibrations, minimizing noise. Proper vibration damping materials help absorb mechanical shocks, preventing noise from resonating through the motor’s housing. Additionally, acoustic insulation plays a *vital* role in containing sound within the motor enclosure. By lining the motor’s casing with sound-absorbing materials, you can *considerably* diminish the noise that escapes into the environment. These techniques are commonly used in industry to improve operational quietness. While mechanical and electrical factors do contribute to noise, implementing vibration damping and acoustic insulation can make a noticeable difference, challenging the notion that all DC motors are naturally loud. Incorporating soundproofing techniques can further enhance noise reduction and create a quieter working environment. Understanding noise mitigation strategies can help in designing quieter motor systems that meet specific operational requirements.

Factors That Influence Noise Levels in DC Motors

Your DC motor’s noise levels are affected by mechanical wear and alignment issues, which can cause vibrations and rattling sounds. Electrical noise sources, like brush sparking and commutation, also contribute to increased noise. Understanding these factors helps you identify and reduce unwanted sounds effectively. Additionally, Hyundai Tuning techniques can optimize motor components for quieter operation, and paying attention to proper maintenance can significantly extend the lifespan of your motor while minimizing noise issues.

Mechanical Wear and Alignment

Mechanical wear and misalignment are primary factors that can substantially increase noise levels in DC motors. When components wear out, vibration patterns become irregular, leading to louder operation. Misaligned shafts or bearings cause uneven forces, amplifying noise and potentially damaging the motor further. Lubrication issues also play a role by increasing friction, which intensifies wear and vibrations. To minimize noise caused by these factors, you should:

- Regularly inspect for signs of mechanical wear.

- Ensure proper alignment during maintenance.

- Use appropriate lubrication to reduce friction.

- Replace worn bearings promptly.

- Monitoring sound patterns can help detect early signs of sound vibrations, which are often indicative of underlying mechanical issues. Additionally, understanding how automation technologies influence maintenance practices can aid in early detection and prevention of noise-related problems. Incorporating predictive maintenance strategies can further reduce unexpected failures and noise escalation.

Addressing these issues helps maintain smooth operation and prevents noise escalation, keeping your motor quieter and more reliable. Proper upkeep ensures mechanical integrity and reduces the risk of noise-related failures.

Electrical Noise Sources

Electrical noise in DC motors arises from various sources within the motor’s electrical system, which can profoundly impact performance and noise levels. Thermal effects generate electrical fluctuations as components heat up, causing changes in resistance that produce noise. Magnetic interference occurs when external magnetic fields or fluctuations within the motor’s magnetic circuit induce unwanted voltages and signals, increasing noise levels. These factors can lead to inconsistent operation and increased acoustic emissions. Variations in temperature alter electrical characteristics, amplifying noise, while magnetic interference disrupts the stable flow of current, generating electromagnetic noise. Understanding these electrical noise sources helps you identify how thermal effects and magnetic interference contribute to overall noise, enabling better design choices and noise mitigation strategies for quieter, more reliable DC motors. Additionally, market growth projections highlight the importance of developing quieter motor technologies to meet increasing demand for efficient and silent operation. As advancements in electrical design continue, implementing effective shielding and cooling methods can significantly reduce electromagnetic and thermal noise, further improving motor performance and longevity. Recognizing the role of electrical components in generating noise can guide engineers in selecting materials and configurations that minimize these disturbances.

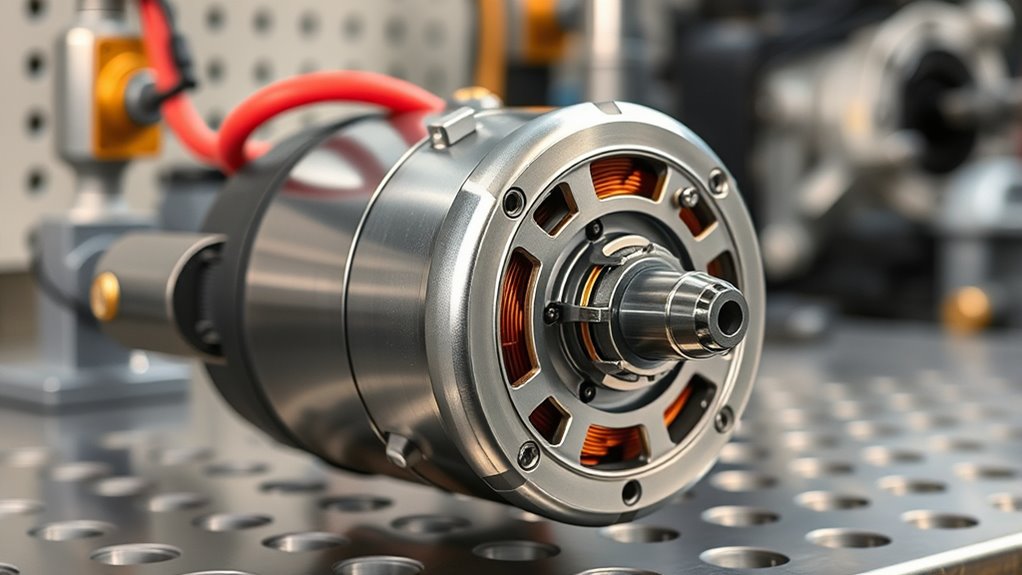

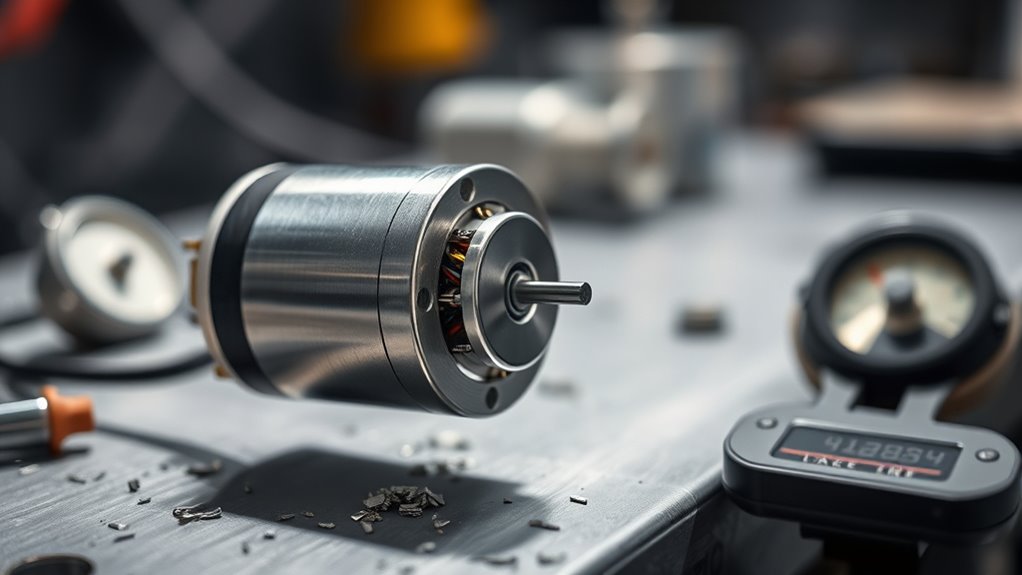

The Role of Motor Design and Construction

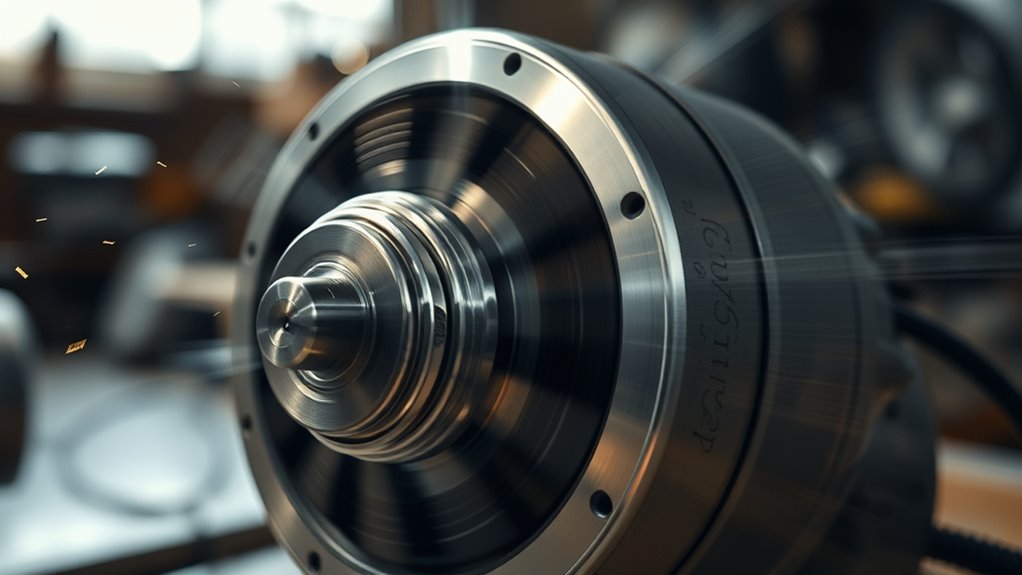

The design and construction of a DC motor considerably influence the amount of noise it produces. You can reduce noise by focusing on key aspects like motor lubrication, which minimizes friction and vibration. Proper lubrication ensures smoother operation and less vibration that causes noise. Vibration analysis helps identify imbalances or misalignments early, allowing for design adjustments. Additionally, the materials used in construction, such as soft mounting and balanced rotors, play an essential role. The motor’s construction impacts how vibrations propagate, affecting sound emission. The choice of materials can also influence the durability and noise levels of the motor. The enclosures and housing designs can dampen noise, making the motor quieter during operation. By paying attention to these factors, you can notably control and minimize noise related to motor design and construction. Kia Tuning offers insights into how design modifications can influence overall performance and noise levels in various motor applications.

How Operating Conditions Affect Sound Emission

Your motor’s sound changes depending on how you operate it. When the load varies, noise levels can increase or decrease, and voltage fluctuations affect the sound quality. Temperature also plays a role, influencing how loud the motor becomes during prolonged use. Additionally, the materials used in the motor’s construction can impact its noise emission characteristics. The type of motor design can also influence how much noise is produced during operation. Moreover, advancements in noise reduction techniques are helping to make motors quieter across various applications.

Load Variations Impact Noise

Load variations considerably influence the noise produced by a DC motor, as changes in the load directly affect the motor’s operating conditions. When the load fluctuates, the motor experiences different vibration patterns, which can increase noise levels. To manage this, you should focus on vibration analysis to detect abnormal vibrations caused by load shifts. Additionally, improving acoustic insulation around the motor can help reduce sound transmission. Here are key points to consider:

- Sudden load changes can cause resonance, amplifying noise.

- Consistent loads lead to smoother operation and quieter sound emission.

- Vibration analysis helps identify and mitigate noise sources.

- Proper acoustic insulation minimizes transmitted noise, improving environment comfort.

- AI-powered diagnostics can assist in predictive maintenance, reducing unexpected load variations and noise levels. Moreover, selecting components designed for low-noise operation can further enhance overall noise reduction.

Voltage and Speed Effects

Have you ever wondered how voltage and speed settings influence the noise your DC motor produces? Increasing voltage often raises the motor’s speed, which can amplify vibrations and produce more sound. Higher speeds also intensify magnetic interference within the motor, leading to additional noise sources. Conversely, lowering voltage reduces both speed and noise, but may cause irregular magnetic interactions. Rapid changes in operating speed can lead to thermal expansion of motor components, altering clearances and causing rattling or additional vibrations. These sound variations are directly tied to how the motor’s magnetic fields interact under different voltages and speeds. Understanding these effects helps you optimize operating conditions to minimize noise while maintaining efficiency. Proper control of voltage and speed can markedly reduce unwanted sound emissions.

Temperature’s Role in Sound

Temperature markedly influences the sound emitted by a DC motor during operation. As the motor heats up, vibration levels can increase, affecting the quality of sound. Elevated temperatures may lead to material expansion, reducing acoustic insulation and amplifying noise. To better understand these effects, vibration analysis helps identify how temperature shifts impact motor behavior. Additionally, proper cooling and insulation minimize thermal noise, improving overall sound quality. Here are key points to consider: 1. Warmer conditions can cause motor components to expand, increasing vibrations. 2. Reduced acoustic insulation due to heat may allow more noise to escape. 3. Vibration analysis detects early signs of temperature-related noise issues. 4. Effective cooling enhances sound control by stabilizing operating temperatures. thermal noise can also contribute to increased sound levels in high-temperature conditions.

The Impact of Load and Speed on Noise

Ever wonder how changing a DC motor’s load and speed influences its noise levels? Increasing the load often leads to greater vibrations, making vibration analysis essential to identify noise sources. As the motor works harder, mechanical stresses intensify, causing parts to vibrate more and generate sound. Higher speeds can amplify these vibrations, resulting in increased noise. To manage this, acoustic insulation becomes crucial; properly insulating the motor reduces sound transmission and dampens vibrations. Adjusting load and speed without considering their impact on vibration levels can lead to louder, less efficient operation. By monitoring vibration analysis and applying effective acoustic insulation, you can better control noise, ensuring quieter and more reliable motor performance under varying load and speed conditions.

Myths About Noise and Motor Size

Many believe that bigger motors are always quieter, but that’s not necessarily true. Noise levels actually depend more on the motor’s design than its size. Understanding this can help you choose the right motor for your needs.

Larger Motor Means Quieter

A common misconception is that larger motors automatically run quieter than smaller ones. In reality, size alone doesn’t determine noise levels. You might think a bigger motor reduces vibration, but without proper vibration analysis, it can produce more noise due to imbalance or resonance. Similarly, relying solely on size ignores the importance of acoustic insulation, which can profoundly cut down noise regardless of motor dimensions. Larger motors often require more robust mounting and better insulation to prevent noise transmission. Here are some key points:

- Vibration analysis helps identify sources of unwanted noise in larger motors.

- Proper mounting reduces vibrations that cause noise.

- Acoustic insulation can dampen noise emissions effectively.

- Motor size isn’t a guarantee of quiet operation—design and isolation matter most.

Noise Depends on Design

While motor size can influence noise levels, it’s ultimately the design that determines how loud a motor will be during operation. A well-designed motor minimizes noise by optimizing lubrication efficiency, reducing friction that causes sound. Proper lubrication ensures smoother operation and less vibration, directly impacting noise output. Additionally, design choices like shielding and layout help manage magnetic interference, which can generate unwanted noise. Poorly planned designs often lead to increased vibrations and electromagnetic disturbances, making the motor louder. So, even a smaller motor can be noisier if its design doesn’t account for lubrication and magnetic interference. Ultimately, noise isn’t just about size—it’s about how thoughtfully the motor is engineered to operate quietly and efficiently.

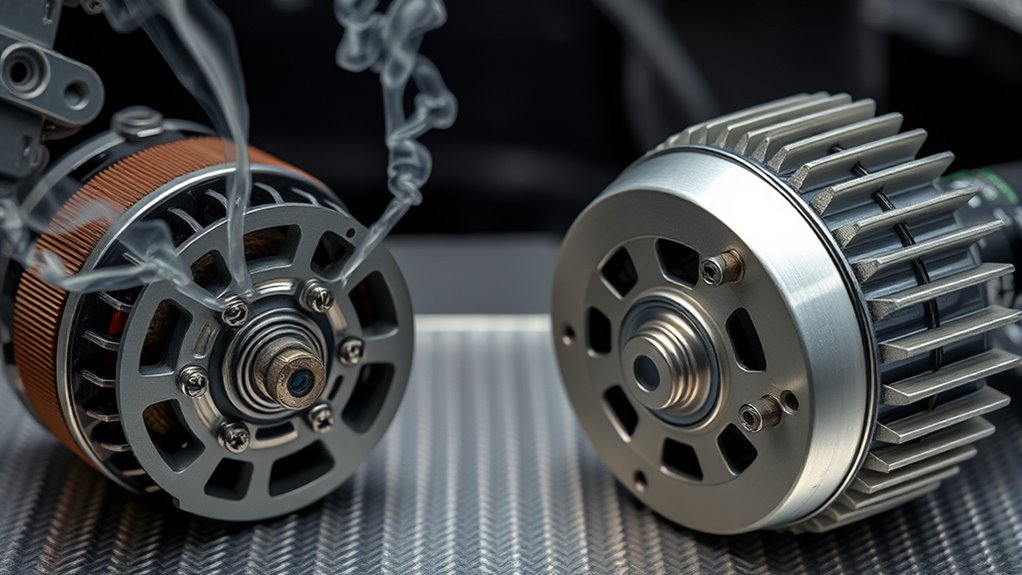

Noise Levels: Brushless Vs Brushed DC Motors

Brushless DC motors typically generate less noise than their brushed counterparts due to the absence of brushes and commutators that create mechanical friction and electrical sparking. This reduction leads to quieter operation and fewer vibrations. However, noise levels can still vary based on factors like lubrication issues and manufacturing tolerances.

Consider these points:

- Brushless motors avoid contact wear, decreasing noise caused by friction.

- Brushed motors may produce more noise due to brush sparking and mechanical contact.

- Variations in manufacturing tolerances can lead to imbalances, increasing noise in both types.

- Lubrication issues in brushed motors can cause additional grinding sounds over time.

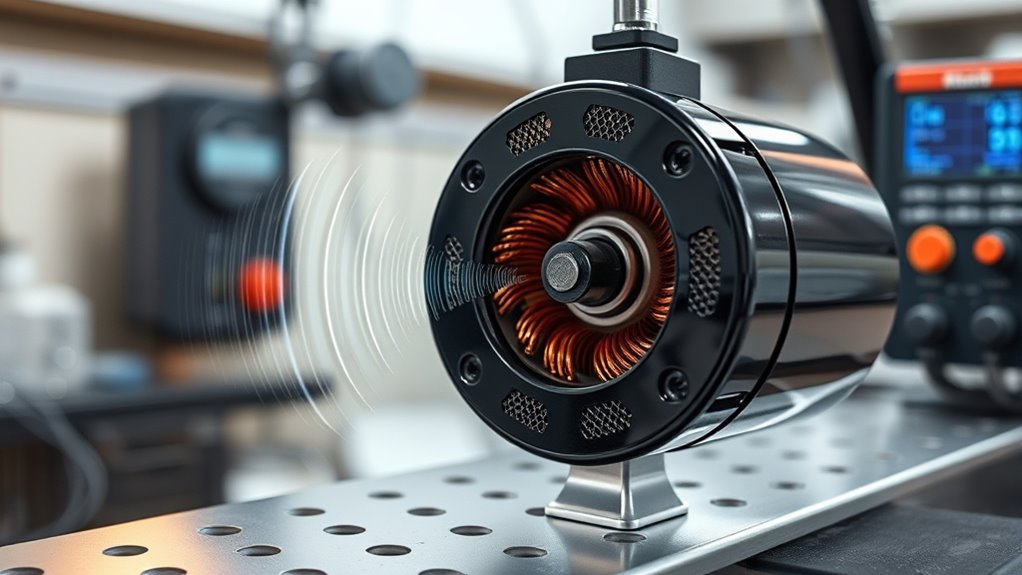

Measuring and Comparing Motor Noise

To accurately compare the noise levels of different DC motors, you need reliable measurement techniques that capture sound intensity and frequency. Using a decibel meter helps measure overall sound levels, but for detailed insights, vibration analysis is essential. It pinpoints the source of noise by detecting vibrations in motor components, revealing how design influences sound output. Incorporate acoustic insulation during testing to minimize external noise interference, ensuring accurate readings. Comparing these measurements across motors allows you to identify models with quieter operation and understand how design factors impact noise. Precise measurement methods help dispel myths about motor noise, providing a factual basis for evaluating performance and guiding noise reduction efforts effectively.

Practical Tips for Reducing Noise in DC Motors

By implementing practical noise reduction techniques, you can considerably improve your DC motor’s quietness and performance. Start with vibration analysis to identify and mitigate sources of mechanical vibrations, which often cause noise. Next, enhance acoustic insulation around the motor to absorb sound waves and reduce noise transmission. Consider balancing the rotor precisely, as imbalance increases vibration and sound. Ultimately, use dampers or mounts designed to absorb vibrations, minimizing noise generated by motor operation. These methods not only quiet your motor but also prolong its lifespan. By focusing on vibration analysis and acoustic insulation, you target the root causes of noise, ensuring a quieter, more efficient motor environment.

When Noise Indicates a Problem

Unusual or persistent noise from your DC motor often signals a problem that needs attention. If you notice irregular sounds, consider vibration analysis to identify imbalance or misalignment issues. This technique helps pinpoint the source of excessive vibrations that can cause motor damage over time. Additionally, acoustic diagnostics can reveal specific noise patterns associated with bearing wear, loose parts, or electrical faults. By listening carefully and analyzing the sound signatures, you can detect early signs of trouble before major failures occur. Addressing these issues promptly ensures your motor runs smoothly and extends its lifespan. Regularly combining vibration analysis with acoustic diagnostics offers an extensive approach to diagnosing motor problems, saving you time and costly repairs down the line.

Frequently Asked Questions

How Does Ambient Temperature Affect DC Motor Noise Levels?

Ambient temperature effects your DC motor noise levels by influencing how parts expand through thermal expansion. As temperatures rise, components may expand slightly, causing increased vibrations or rubbing, which can lead to louder noise. Conversely, cooler temperatures reduce thermal expansion, often resulting in quieter operation. So, controlling ambient temperature helps manage noise levels, ensuring your motor runs smoothly without unnecessary vibrations caused by thermal effects.

Can Lubrication Methods Influence the Noise Emitted by DC Motors?

Did you know that improper lubrication can increase DC motor noise by up to 50%? Yes, lubrication techniques directly impact noise levels. Using the right material selection for lubricants reduces friction and vibration, leading to quieter operation. Regular maintenance ensures ideal lubrication, preventing noise caused by worn or dry components. So, choosing appropriate lubrication methods and materials isn’t just about efficiency—it’s about keeping your motor running smoothly and quietly.

Are There Specific Materials That Help Reduce Motor Noise?

You can reduce motor noise by choosing materials with good damping properties and vibration isolation capabilities. Material damping absorbs vibrations, preventing them from becoming noise, while vibration isolation decouples the motor from its surroundings, minimizing sound transmission. Using rubber mounts or specialized damping pads made from these materials can markedly lower noise levels, making your motor operation quieter and more efficient.

How Does Electromagnetic Interference Impact Perceived Noise?

Imagine electromagnetic interference (EMI) as a thunderstorm inside your motor, amplifying perceived noise to deafening levels. EMI disrupts the motor’s electromagnetic balance, causing increased vibration and noise. Using vibration damping materials and acoustic insulation can help tame this chaos, reducing the noise you hear. So, EMI considerably impacts perceived noise, but you can combat it by strategically applying damping and insulation techniques to keep your motor’s sound under control.

What Are Emerging Technologies to Minimize DC Motor Noise?

You can reduce DC motor noise by adopting emerging technologies like advanced acoustic dampening materials and noise cancellation systems. These innovations actively target sound waves and vibrations, minimizing noise output. By integrating smart damping techniques and real-time noise cancellation, you’ll experience quieter motor operation. These solutions are becoming more efficient and affordable, making it easier for you to maintain quieter environments in industrial or residential settings.

Conclusion

Understanding the truths behind DC motor noise is like peeling back layers of an onion—you find that many factors, from design to operating conditions, influence sound levels. By knowing what’s myth and what’s reality, you can make smarter choices to reduce noise effectively. Remember, tuning your motor is like adjusting a musical instrument—you’ll achieve harmony and quiet, transforming a noisy nuisance into a smooth, silent operation.