The evolution of blade shapes from flat to aerodynamic designs improves airflow, efficiency, and noise reduction. Early flat blades faced challenges with drag and vibration, prompting innovations in curved and airfoil shapes that boost performance. Advances in materials and manufacturing, like composites and precise techniques, allowed for complex geometries. Next, computational tools help optimize designs, while surface coatings and adaptive features further enhance aerodynamics. Exploring these developments reveals how technology continues to shape blade performance beyond traditional boundaries.

Key Takeaways

- Early blades were flat, facing limitations in airflow efficiency, leading to higher drag and machine stress.

- The shift to curved and airfoil-shaped blades improved aerodynamic performance by reducing drag and increasing lift.

- Advanced materials and precise manufacturing enabled complex blade geometries, enhancing efficiency and structural integrity.

- Surface finishes and composites minimized turbulence, vibration, and noise, making blades quieter and more environmentally friendly.

- Future innovations include adaptive, biomimetic surfaces and shape-changing designs for optimized performance and sustainability.

Early Flat Blade Designs and Their Limitations

Early flat blade designs marked the initial attempts to create effective cutting tools, but they quickly revealed their limitations. During blade manufacturing, it became clear that flat blades couldn’t optimize airflow or reduce drag, which hampered their efficiency. The flat blade limitations made them less effective at cutting through air or fluid, especially at higher speeds. They lacked the aerodynamic properties needed for improved performance, leading to increased resistance and energy consumption. Additionally, these designs often caused more vibration and stress on the machinery. Recognizing these issues drove innovation, prompting engineers to explore alternative shapes. Understanding the blade shape evolution and the shortcomings of flat blades was essential for advancing blade technology and improving overall efficiency in various applications.

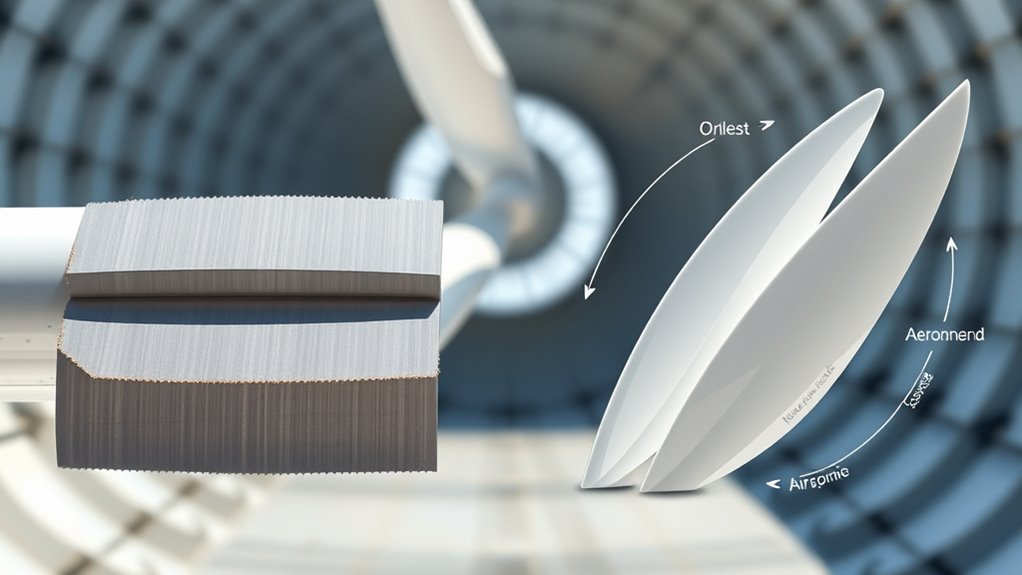

The Rise of Curved and Airfoil-Shaped Blades

You’ll notice that curved and airfoil-shaped blades considerably boost aerodynamic efficiency and reduce noise. However, designing these blades presents structural challenges that require innovative solutions. Exploring these trade-offs reveals why this shape shift has become so influential in blade development. Additionally, advancements in materials technology are enabling engineers to create more durable and lightweight blades, further enhancing performance and longevity. The integration of advanced manufacturing techniques also plays a crucial role in producing precise and complex blade geometries that were previously difficult to achieve. Moreover, manufacturing precision is essential for maintaining the aerodynamic improvements these shapes offer.

Aerodynamic Efficiency Gains

The shift toward curved and airfoil-shaped blades marks a significant advance in aerodynamic efficiency for modern blade designs. These shapes reduce drag and increase lift, allowing turbines and fans to operate more effectively. Improved blade materials, such as composites and lightweight alloys, enhance strength while minimizing weight, boosting overall performance. Advanced manufacturing techniques, like precision casting and additive manufacturing, enable intricate airfoil geometries with high accuracy. This precision guarantees ideal airflow and reduces turbulence around the blades. Additionally, the integration of innovative materials allows for even thinner and more aerodynamically optimized blade profiles. As a result, you experience higher energy output and better fuel efficiency. The combination of innovative materials and manufacturing processes has driven these efficiency gains, making modern blades more effective at capturing energy and improving the performance of wind turbines and other aerodynamic systems.

Noise Reduction Benefits

As curved and airfoil-shaped blades become more common, they also help reduce noise generated by aerodynamic interactions. The streamlined shape minimizes turbulent airflow and vortex shedding, which are primary noise sources. Using advanced blade materials, such as composites, helps dampen vibrations that contribute to noise. Additionally, modern manufacturing techniques like precision casting and additive manufacturing enable the creation of smoother, more accurate blade surfaces, further decreasing noise emissions. These innovations allow for tighter tolerances and better surface finishes, reducing aerodynamic noise without sacrificing strength. Furthermore, aerodynamic efficiency improvements in blade design contribute to quieter operation by optimizing airflow patterns around the blades. The integration of noise mitigation strategies in blade development enhances overall environmental compatibility. Incorporating sustainable manufacturing practices also reduces the environmental footprint of production processes. Overall, the shift to curved and airfoil designs, combined with improved materials and manufacturing processes, notably enhances noise reduction, making turbines quieter and more environmentally friendly.

Structural Design Challenges

What are the main structural challenges when designing curved and airfoil-shaped blades? You need to guarantee the blade material can handle increased aerodynamic stresses without compromising strength. The curved shapes create complex load distributions, making it harder to maintain structural integrity. Manufacturing precision becomes critical to achieve the precise curvature and smooth surface required for ideal airflow, but this increases complexity and cost. Variations in material properties or manufacturing defects can lead to weaknesses, risking fatigue or failure over time. You must carefully select high-quality blade materials that balance flexibility and durability. Accurate manufacturing processes help ensure the blades meet design specifications, reducing stress concentrations. Addressing these challenges is essential for creating reliable, efficient blades that withstand operational forces. Additionally, understanding the design principles of farmhouse bedrooms can provide insights into optimizing structural stability and aesthetic appeal in complex blade geometries.

Influence of Aerodynamics on Blade Development

Aerodynamics play a vital role in shaping blade development by reducing drag and increasing efficiency. When you optimize blade designs for better airflow, you enable more lift with less resistance. This balance directly impacts the performance and longevity of blades in various applications. Additionally, innovative materials and design techniques, such as differentiated shapes, further enhance aerodynamic properties and overall effectiveness. Incorporating advanced computational modeling allows engineers to simulate airflow patterns more accurately, leading to more refined and effective blade geometries. Understanding boundary layer control is also crucial for minimizing turbulence and improving airflow over blade surfaces.

Reduced Drag Effects

Ever wondered how blade designs minimize resistance to improve efficiency? Aerodynamic improvements play a key role in reducing drag. Modern blades use advanced blade materials that are lightweight yet strong, decreasing overall resistance. Manufacturing techniques, like precision shaping and surface treatments, smooth airflow over the blade surface. These innovations lower drag forces, boosting performance and energy capture. Additionally, airflow management techniques are employed to further optimize aerodynamics. Improving blade design can significantly enhance efficiency by reducing unnecessary resistance. Optimizing these factors is essential for achieving energy efficiency in turbine and propeller applications.

Enhanced Lift Generation

By optimizing blade shapes and surfaces, designers can substantially enhance lift generation, allowing turbines and propellers to produce more thrust with less energy. Key factors include:

- Blade thinning reduces drag and improves airflow over the surface, increasing lift efficiency. This process also minimizes airflow disruption, leading to smoother operation and more consistent performance.

- Smoother surfaces minimize surface roughness, decreasing turbulent flow and enhancing lift.

- Aerodynamic shaping directs airflow more effectively, creating higher pressure differentials.

- Fine-tuning blade angles optimizes the airflow path, boosting lift without increasing material weight.

- Incorporating aerodynamic principles about aerodynamic principles helps designers make informed decisions to maximize efficiency.

Together, these strategies improve lift by leveraging aerodynamics, enabling blades to generate more thrust while conserving energy. The combination of blade thinning and surface roughness control plays a vital role, ensuring the blades perform at their best across various operational conditions.

Advancements in Material Technology and Manufacturing

Advancements in material technology and manufacturing processes have considerably transformed blade design, enabling you to create more efficient and durable blades. Modern materials, like composites and advanced alloys, offer superior material durability, which extends blade lifespan and reduces maintenance costs. These innovations also allow for lighter, stronger blades that perform better under stress. Manufacturing precision has improved with techniques such as CNC machining and additive manufacturing, ensuring tighter tolerances and consistent quality. This Manufacturing precision reduces defects and enhances aerodynamic performance. Additionally, the adoption of aerospace-grade materials has further improved blade resilience and performance. As a result, blades can be produced with complex geometries that were previously impossible, optimizing airflow and efficiency. Overall, these technological advancements empower you to design blades that are not only more resilient but also more precisely engineered for peak performance.

Computational Fluid Dynamics and Design Optimization

Computational Fluid Dynamics (CFD) has become an essential tool in optimizing blade designs by accurately simulating airflow patterns and aerodynamic forces. With CFD, you can evaluate how different blade shapes impact performance and efficiency. To maximize these benefits, consider these key aspects:

CFD enables precise airflow simulation to optimize blade shape, performance, and efficiency.

- Selecting the right blade material to withstand aerodynamic stresses during simulations.

- Incorporating manufacturing techniques that enable precise blade geometry adjustments based on CFD results.

- Running iterative simulations to refine blade curvature and thickness for improved airflow.

- Using CFD insights to balance aerodynamic performance with manufacturing feasibility.

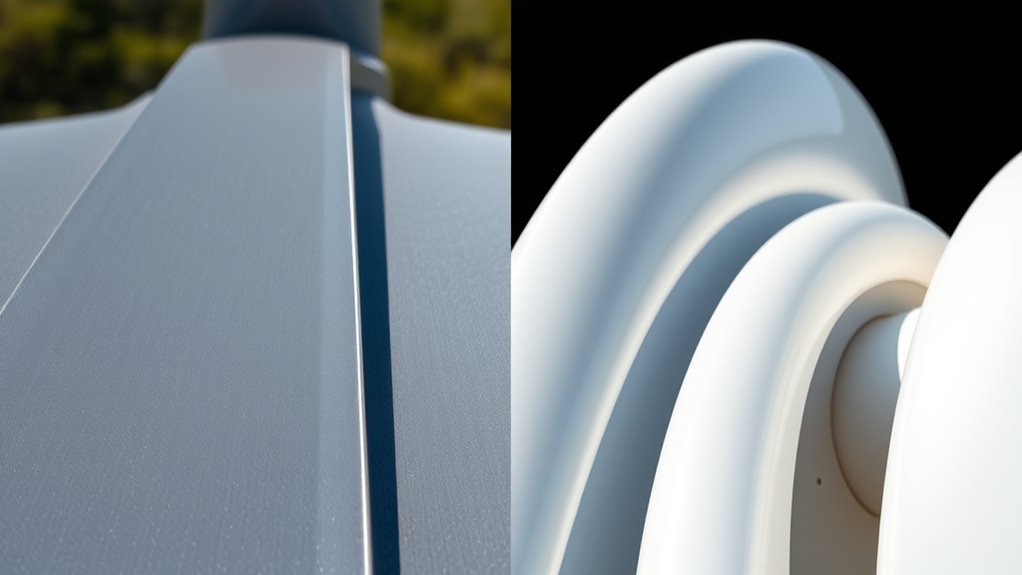

Innovations in Blade Surface Texturing and Coatings

Innovations in blade surface texturing and coatings are transforming aerodynamic performance by reducing drag and delaying flow separation. Biomimicry surfaces mimic nature’s efficient designs, like sharkskin, to create textures that manipulate airflow more effectively. These surfaces disrupt turbulent boundary layers, maintaining smoother airflow and boosting efficiency. Nanocoating technologies further enhance these surfaces by providing durable, hydrophobic, and low-friction layers that resist dirt, corrosion, and erosion. Applying nanocoatings allows blades to maintain highly effective performance over longer periods, reducing maintenance needs. Together, biomimicry surfaces and nanocoatings enable blades to achieve better aerodynamics without altering their fundamental shape. This synergy of natural inspiration and advanced technology is pushing blade design toward higher efficiency, longevity, and performance in various applications.

Adaptive and Variable-Geometry Blade Technologies

Adaptive and variable-geometry blade technologies enable turbines and aircraft engines to optimize performance across diverse operating conditions. They adjust blade shape in real-time, enhancing efficiency and reducing fuel consumption. To achieve this, you consider:

- Selecting advanced blade materials, like composites or high-strength alloys, for durability during shape changes.

- Employing innovative manufacturing processes such as additive manufacturing or precision casting to create complex, adaptable geometries.

- Integrating actuation mechanisms that allow blades to morph shape dynamically.

- Ensuring maintenance and repair protocols accommodate the unique properties of these materials and manufacturing methods.

These technologies leverage sophisticated blade materials and manufacturing processes to deliver blades that can adapt seamlessly, maximizing aerodynamic performance and operational flexibility in various environments.

Future Trends in Blade Shape Innovation

Advancements in blade shape technology are poised to reshape how turbines and aircraft engines operate in the coming years. Future trends focus on improving blade durability to withstand higher stresses and extreme conditions, ensuring longer service life and reduced maintenance. Innovations in material science, such as composites and advanced alloys, will play a key role. Additionally, designers aim to lower manufacturing costs by adopting lightweight, cost-effective manufacturing processes like additive manufacturing and modular designs. These developments will enable more complex, aerodynamic blade shapes without markedly increasing production expenses. As a result, you’ll benefit from more efficient, resilient blades that enhance performance and longevity while keeping costs manageable, paving the way for more sustainable and economically viable energy and aviation solutions.

Frequently Asked Questions

How Do Blade Shapes Affect Overall Energy Efficiency?

Blade shapes directly impact your energy efficiency by influencing airflow and drag. Using advanced blade materials and manufacturing techniques, you can craft blades that are lighter and more aerodynamic, reducing energy loss. These improvements enable turbines to generate more power with less effort, maximizing efficiency. So, selecting the right blade design, material, and manufacturing process helps optimize energy output while minimizing operational costs.

What Environmental Factors Influence Blade Shape Evolution?

You’re curious about what environmental factors influence blade shape evolution. Changes in wind conditions, temperature, and air density drive the need for environmental adaptation, affecting the blade surface design. As wind patterns become more variable or harsh, blades evolve to maximize efficiency and durability. You’ll notice that in different climates, blades adapt their shape to optimize airflow, reduce wear, and improve energy capture, ensuring they perform well in diverse environmental conditions.

Are There Any Emerging Materials for Future Blade Designs?

You’ll find that emerging materials like composite materials are transforming blade designs, offering greater strength and flexibility. Smart sensors are also playing a key role, providing real-time data to optimize performance and detect issues early. These advancements enable you to develop more efficient, durable blades, adapting to changing environmental conditions. Incorporating composite materials and smart sensors guarantees your blades stay at the forefront of innovation, improving safety and efficiency.

How Do Blade Shapes Impact Noise Generation?

You might notice that blade shapes markedly impact noise generation, especially through blade vortex interactions. Aerodynamic designs help reduce these vortex effects, minimizing noise. Additionally, modern blades incorporate sound dampening features to absorb and deflect sound waves, making operation quieter. By optimizing blade shape, manufacturers can cut down on disruptive noise, leading to smoother, more efficient performance and a better experience for users near turbines or aircraft.

What Role Does Machine Learning Play in Blade Design?

It’s often said that machine learning quietly transforms blade design. You can leverage data-driven modeling to uncover subtle patterns, enabling smarter design optimization. By analyzing vast datasets, machine learning guides you in improving aerodynamic performance and reducing noise. It acts as a powerful tool, helping you make informed decisions faster, ultimately refining blade shapes with greater precision and efficiency—making your designs more innovative and effective without the need for trial-and-error.

Conclusion

As you explore the evolution from flat to aerodynamic blades, it’s clear that innovation drives progress. Imagine the future as a canvas, waiting for your ideas to shape tomorrow’s blades—where every curve and coating tells a story of mastery and discovery. Embrace the journey, for in the dance of design and technology, your contribution could redefine performance and efficiency. The horizon beckons—are you ready to shape it?