Few realize that DC motors deliver precise speed control, high torque at low speeds, and quiet operation, making them ideal for many applications. Their compact design means you can use them in tight spaces, while their energy efficiency helps lower power costs. Plus, they are easy to maintain and integrate with modern electronic controls, supporting automation and smart systems. If you keep exploring, you’ll uncover just how versatile and beneficial DC motors can truly be.

Key Takeaways

- DC motors offer precise speed control and smooth operation with minimal noise.

- They deliver high torque at low speeds, making them ideal for demanding tasks.

- Compact design and versatile mounting options suit various applications and space constraints.

- Easy maintenance and long lifespan reduce operational costs and increase reliability.

- Modern control technologies enable automation, energy efficiency, and expansion into smart systems.

Superior Speed Control and Precision

Because of their design, DC motors offer exceptional speed control and precision. By adjusting voltage regulation, you can finely tune the motor’s speed to match your needs, whether for small adjustments or rapid changes. This control allows for smoother operation and better performance in various applications. Additionally, DC motors excel at noise reduction, making them ideal for environments where quiet operation is essential. Their ability to maintain consistent speed with minimal noise enhances user experience and system reliability. This combination of precise speed regulation and low noise output makes DC motors highly versatile, especially in tasks requiring accuracy and quiet operation. Furthermore, employing vertical storage solutions can optimize space management around the motor setup, creating a more organized workspace. Overall, their design empowers you to achieve ideal performance with maximum control and minimal disturbance.

High Torque at Low Speeds

One of the standout features of DC motors is their ability to produce high torque even at low speeds. This is due to their favorable torque characteristics, which allow for strong rotational force without needing high RPMs. When operating at low speed performance, DC motors maintain consistent torque output, making them ideal for applications requiring precise control and strong starting power. You’ll find this especially useful in tasks like lifting, conveyors, or robotic movements, where maximum torque is needed without increasing speed. Unlike other motor types, DC motors deliver smooth and reliable torque at low speeds, ensuring efficient operation and better control. Additionally, their easy speed control capability allows for fine-tuning performance to match specific operational needs. This combination of high torque and stable low-speed performance makes DC motors a versatile choice for many demanding applications.

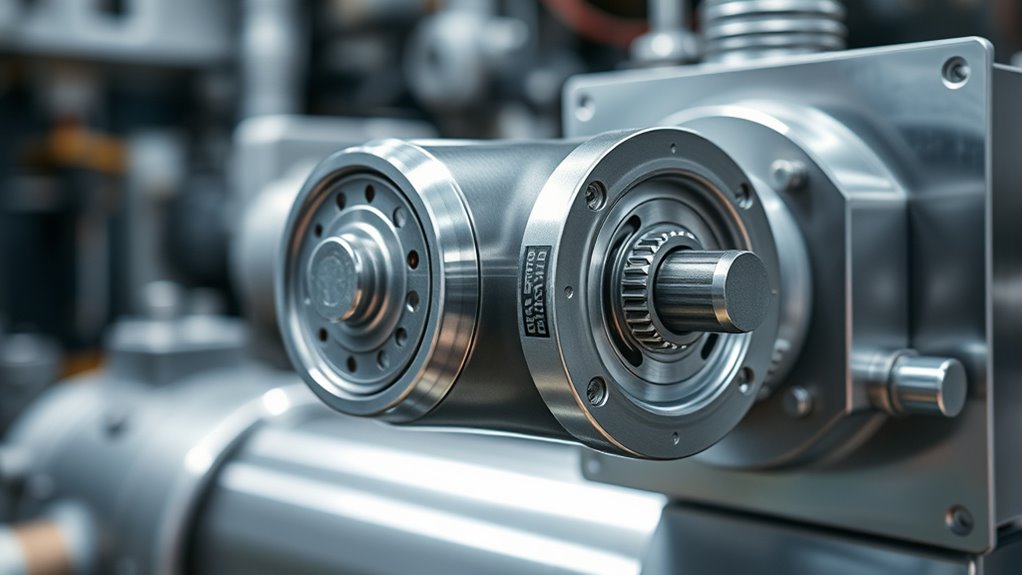

Compact Design and Versatility

Dc motors feature a space-saving design that fits into tight spaces easily. You can also choose from various mounting options to suit different setups. Their versatility allows them to work across a wide range of applications, making them highly adaptable. Additionally, performance tuning can further enhance their efficiency and functionality in specialized tasks.

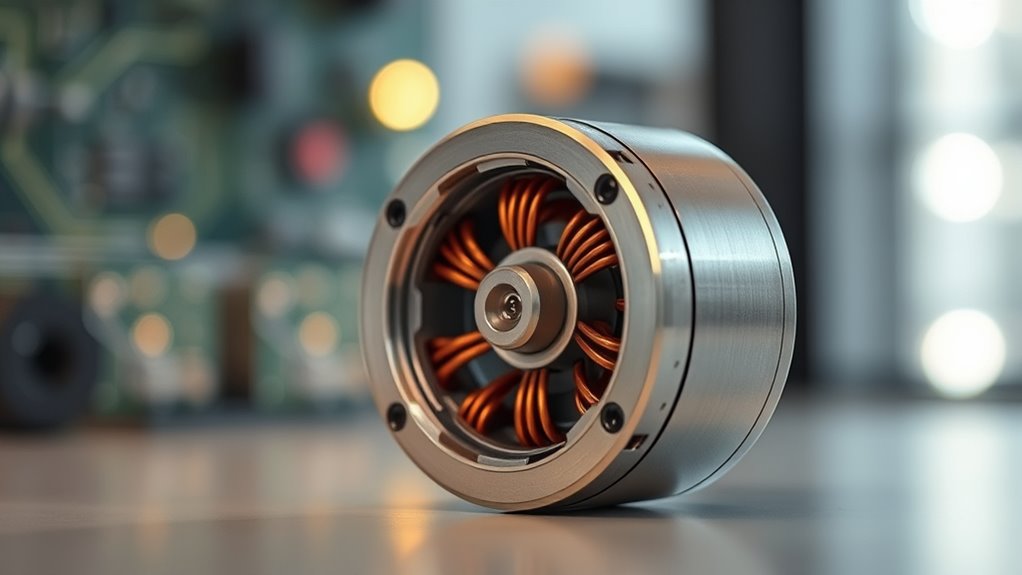

Space-Saving Form Factor

Have you ever needed a motor that fits seamlessly into a tight space without sacrificing performance? Dc motors offer a compact design that maximizes space efficiency, making them ideal for small devices and embedded systems. Their space-saving form factor doesn’t compromise power or reliability, allowing you to create versatile applications without bulky components. Because of their size, they also tend to have lower noise levels, providing quieter operation in sensitive environments. Additionally, their efficient design helps conserve battery life, extending the operational time of portable devices. This combination of a small footprint, quiet performance, and energy efficiency makes dc motors a smart choice for space-constrained projects where performance and durability are essential. Moreover, their power-to-size ratio ensures that even small motors can deliver substantial torque and efficiency, broadening their range of applications.

Flexible Mounting Options

Thanks to their compact design, dc motors can be mounted in a variety of ways to suit different applications. This mounting versatility allows you to choose from numerous installation options, making integration easier in tight or unconventional spaces. Whether you prefer flange, face, or foot mounting, these options give you flexibility to optimize performance. The table below highlights common mounting types:

| Mounting Type | Description | Best For |

|---|---|---|

| Flange Mount | Motor attached via flange holes | Horizontal, stable |

| Foot Mount | Base with mounting holes | Compact setups |

| Face Mount | Front face secured directly | Space-limited areas |

This versatility simplifies installation, enabling you to adapt the motor to your specific design needs seamlessly. Self Watering Plant Pots

Diverse Application Compatibility

The compact design and versatile mounting options of dc motors enable them to adapt seamlessly to a wide range of applications. Their small size allows easy integration into devices with limited space, from robotics to household appliances. You’ll find them compatible with various power supplies, making setup straightforward across different systems. Their versatility also means you can use them for precise control in automation or simple tasks like fans and pumps. Because of their simple construction, maintenance routines are minimal, saving you time and effort. Their ability to operate efficiently under different conditions makes them a reliable choice for diverse projects. Additionally, advancements in motor control technology have improved their efficiency and performance even further. Overall, this adaptability simplifies your design process and ensures your application remains flexible as requirements evolve.

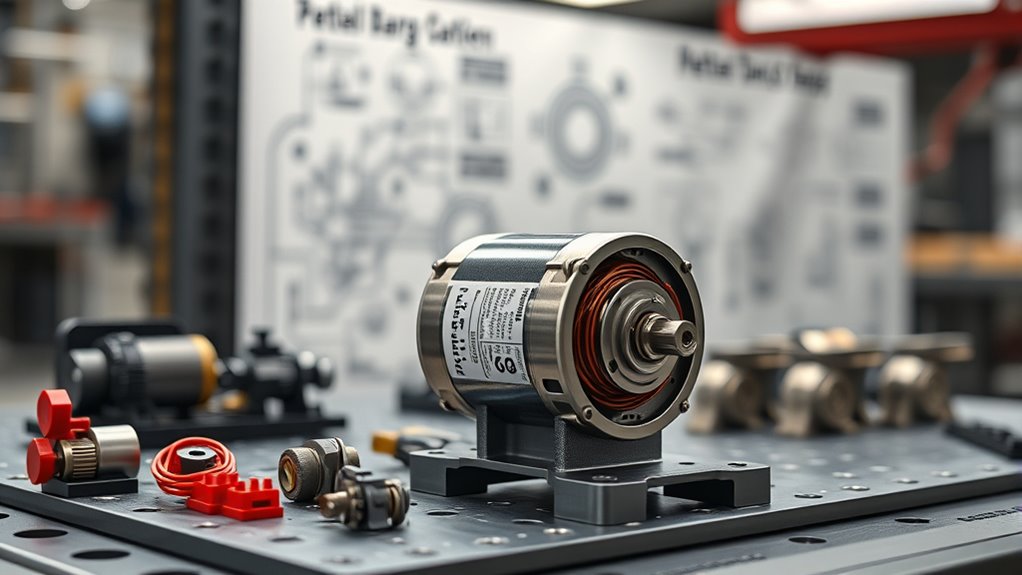

Cost-Effective Maintenance and Longevity

Dc motors are known for their easy repair processes, which help you save both time and money. Their durable operational life means you won’t need frequent replacements, reducing ongoing costs. This combination makes them a smart, long-term choice for your projects. Additionally, proper maintenance can further extend their lifespan and improve performance preventative care approaches.

Easy Repair Processes

Because they are designed with simple components, dc motors are easy to repair and maintain, which helps keep costs low. Their straightforward structure means you won’t need specialized tools or extensive expertise. Maintenance mainly involves checking lubrication needs and inspecting wiring complexity. These tasks are quick and cost-effective, reducing downtime and expenses. With minimal parts to replace, repairs are straightforward, saving you time and money. Here’s a quick overview:

| Aspect | Advantage | Tips |

|---|---|---|

| Lubrication needs | Easy to apply, extends motor life | Regular lubrication check |

| Wiring complexity | Minimal wiring reduces issues | Inspect connections periodically |

| Repair process | Simple and quick to perform | Use standard tools |

| Maintenance cost | Low due to simple design | Schedule routine checks |

This simplicity guarantees your motor stays operational longer with less hassle.

Durable Operational Life

Thanks to their simple design and easy maintenance, dc motors are built to last. Good thermal management is key; they efficiently dissipate heat, preventing overheating and extending operational life. This helps reduce wear and tear on components, lowering repair costs over time. Additionally, dc motors operate with noise reduction, making them suitable for environments where quiet operation is important. Their durable construction means fewer replacements and less downtime, saving you money. Regular maintenance keeps the motor running smoothly, ensuring longevity and consistent performance. By choosing a dc motor with effective thermal management and noise reduction features, you benefit from a cost-effective, long-lasting solution that minimizes maintenance efforts and maximizes operational efficiency.

Efficient Energy Consumption

Have you ever wondered how to reduce energy costs while maintaining reliable performance? Dc motors excel at efficient energy consumption, helping you achieve significant power savings. Their design minimizes energy loss, making them more energy-efficient compared to other motor types. This efficiency translates into lower electricity bills and a smaller environmental footprint. To illustrate, here’s a quick comparison: Mazda Tuning can also benefit from understanding motor efficiencies to optimize vehicle performance and longevity.

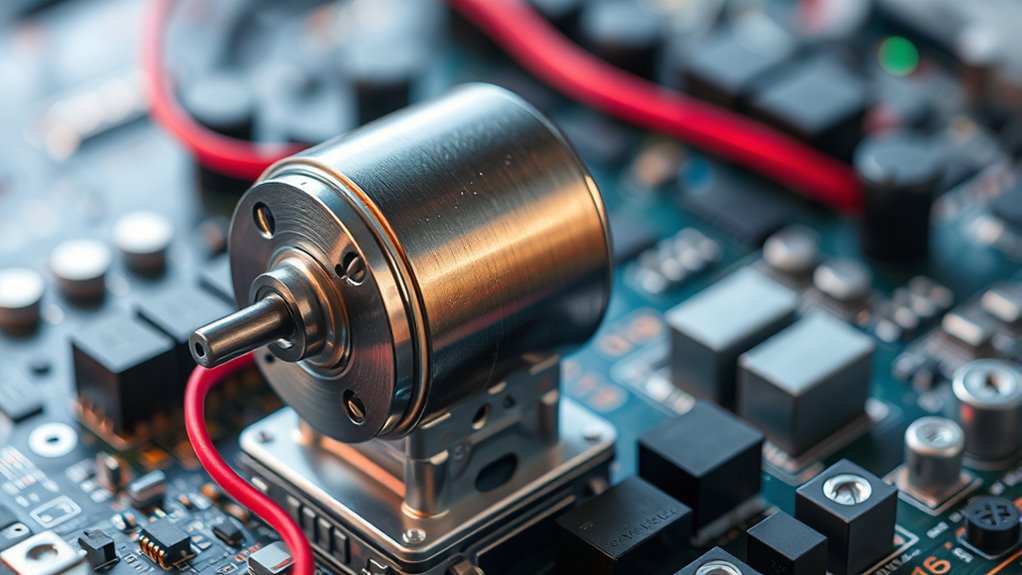

Ease of Integration With Electronic Controls

One of the key advantages of DC motors is their seamless compatibility with electronic control systems. Their design allows for straightforward electronic interfacing, making control system integration simple and efficient. You can easily adjust speed, torque, and direction with minimal hardware modifications, which streamlines development. This compatibility means you don’t need specialized components or complex wiring, saving time and costs. Additionally, DC motors respond quickly to control inputs, offering precise operation. The ease of integration also enables automation and remote control, enhancing functionality. Vetted

Wide Range of Applications Across Industries

DC motors’ versatility makes them ideal for a wide array of industries, where their ease of control and reliable performance can be fully utilized. In power generation, they help optimize turbine operation and facilitate efficient energy conversion. Their precise control is essential for maintaining stability and efficiency in these systems. In the medical device sector, DC motors power equipment like pumps, ventilators, and diagnostic tools, ensuring smooth and accurate operation vital for patient care. Their compact size and consistent torque make them suitable for space-constrained applications. Across manufacturing, automation, and transportation, DC motors deliver dependable performance, reducing downtime and maintenance costs. Their adaptability across such diverse fields highlights their importance in advancing technology and boosting productivity worldwide. Additionally, the development of advancements in motor technology, such as smart controls and variable speed systems, continues to expand their capabilities and applications.

Fast Response and Dynamic Performance

The ability to respond quickly to changing conditions is one of the key advantages of DC motors. This fast response enables precise control over speed and torque, making them ideal for dynamic applications. Their quick acceleration and deceleration improve overall system performance while maintaining power efficiency. Especially, DC motors operate with lower noise levels during rapid adjustments, reducing noise pollution in sensitive environments. To maximize their benefits, consider these points:

DC motors offer rapid response, precise control, and quiet operation for dynamic applications.

- Precise speed control enhances responsiveness

- Quick torque adjustments improve system adaptability

- Power efficiency minimizes energy waste during rapid changes

- Low noise levels support quieter operation in critical settings

- Incorporating modern technologies can further enhance performance and control capabilities

Scalability for Small to Large Projects

Thanks to their quick response and precise control, DC motors can be effectively scaled to suit a wide range of project sizes. Whether you’re working on small gadgets or large industrial systems, DC motors adapt well, offering flexibility. However, scalability challenges can arise, especially when integrating multiple motors or upgrading systems. Larger projects may require more complex wiring and power management, increasing installation complexity. You might find that managing multiple units demands careful planning to ensure consistent performance and avoid wiring issues. Despite these challenges, DC motors remain a reliable choice because they can be customized and scaled efficiently. For example, tuning techniques can help optimize performance at any scale. With proper planning and understanding of installation requirements, you can minimize complexity and ensure your project benefits from their versatility at any size.

Frequently Asked Questions

How Do DC Motors Compare to AC Motors in Efficiency?

You’ll find that DC motors generally offer higher power efficiency than AC motors, especially in variable speed applications. This means they consume less energy to perform the same task, reducing energy consumption and operational costs. Their ability to provide precise control makes them ideal for applications where efficiency and adaptability matter. So, if you’re looking to maximize energy savings, DC motors often outperform AC motors in efficiency.

What Are Common Issues Faced With DC Motor Maintenance?

Like tending a delicate garden, maintaining your DC motor requires regular attention. Common issues include brush wear, which calls for thorough brush inspection, and lubrication maintenance, essential for smooth operation. Failing to monitor these can cause overheating or mechanical failure. Addressing these issues proactively keeps your motor humming along efficiently, preventing costly downtime. Remember, consistent care transforms maintenance from a chore into a safeguard for your equipment’s longevity.

Can DC Motors Operate Reliably in Extreme Environments?

Yes, DC motors can operate reliably in extreme environments if you choose models with high thermal stability and corrosion resistance. These features help the motor withstand temperature fluctuations and harsh conditions like moisture or chemicals. By selecting motors designed for such environments, you guarantee consistent performance and longevity, reducing maintenance needs. Proper insulation and protective coatings also contribute, making your DC motor a dependable choice even in challenging settings.

How Does Temperature Affect DC Motor Performance?

Temperature can be a double-edged sword for your DC motor, like a wildfire spreading unpredictably. As thermal effects kick in, performance drops if the motor overheats, causing efficiency loss and potential damage. Proper temperature regulation is key to maintaining reliability and longevity. Keep an eye on cooling systems and ambient conditions to guarantee your motor runs smoothly, no matter the heat challenges it faces.

Are There Safety Concerns Specific to DC Motor Operation?

You should be aware that safety concerns in DC motor operation include electrical hazards and mechanical risks. Brushless advantages make them safer and more reliable, reducing sparks and wear. Always follow safety precautions like proper insulation, grounding, and protective gear. Regular maintenance and correct installation minimize risks, ensuring safe and efficient operation. Staying vigilant and adhering to safety guidelines helps prevent accidents and prolongs your motor’s lifespan.

Conclusion

While DC motors quietly enhance your projects with their remarkable control and reliability, their true potential often remains beneath the surface. Embracing their benefits can lead to smoother operations and greater innovations, even when the full extent isn’t immediately obvious. By understanding and appreciating these hidden advantages, you open the door to more efficient, versatile solutions that can inspire confidence and spark new possibilities in your endeavors. Sometimes, the most valuable aspects are the ones you discover along the way.