To maintain the ideal balance between RPM and CFM, regularly inspect and calibrate your equipment to guarantee components are aligned and measurements are accurate. Lubricate moving parts properly to reduce friction and monitor system performance through real-time data. Implement preventive maintenance schedules and train staff on proper procedures. Staying consistent with these practices helps prevent issues and keeps airflow optimized. Keep going to discover more tips for perfect RPM versus CFM performance.

Key Takeaways

- Regularly inspect and calibrate system components to ensure RPM and CFM are within manufacturer specifications.

- Maintain proper lubrication of moving parts to reduce friction and prevent performance fluctuations.

- Monitor real-time data for deviations in RPM and airflow, allowing proactive adjustments and troubleshooting.

- Schedule preventive maintenance based on usage patterns and system performance data to sustain optimal levels.

- Train staff thoroughly on maintenance procedures to ensure consistency and accuracy in managing RPM and CFM.

Understanding the Relationship Between RPM and CFM

Understanding the relationship between RPM (revolutions per minute) and CFM (cubic feet per minute) is essential for maintaining efficient equipment. You need to grasp how airflow dynamics influence this relationship, as higher RPMs typically increase airflow, but pressure fluctuations can affect performance. When RPM changes, it alters the airflow velocity, impacting CFM output. However, pressure fluctuations within the system can cause inconsistent airflow, reducing efficiency. Recognizing how these factors interact helps you optimize operational parameters. You can better predict how adjustments in RPM will influence airflow, ensuring you maintain proper CFM levels. This understanding allows you to troubleshoot issues effectively, prevent airflow disruptions, and keep your equipment running smoothly and efficiently. Additionally, understanding sound vibrations and frequencies can contribute to optimizing system performance and health.

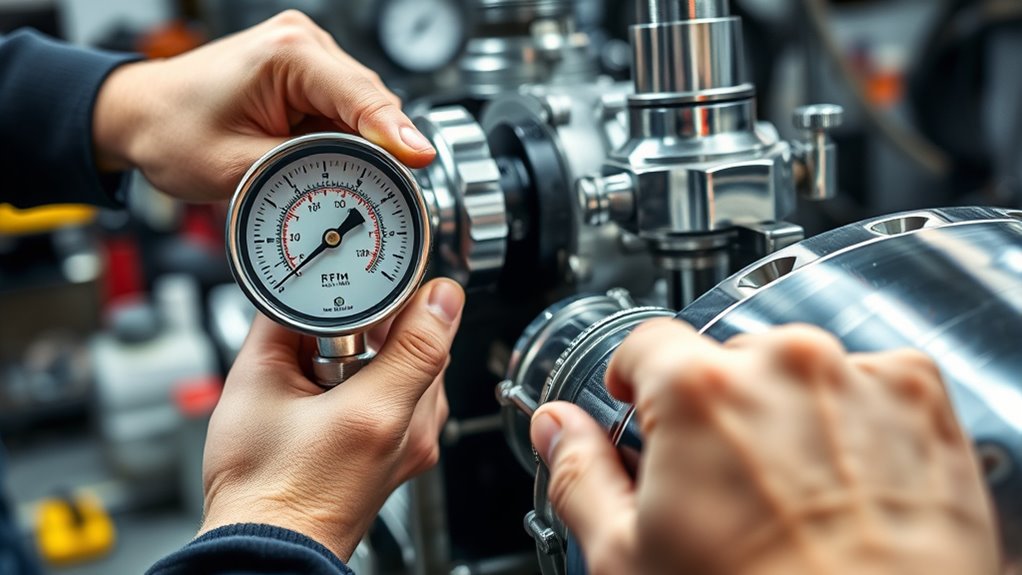

Regular Inspection and Calibration of Components

Regularly inspecting and calibrating the components of your airflow system guarantees it operates at peak efficiency. Check for proper component alignment to assure airflow isn’t disrupted and that measurements stay accurate. Misaligned parts can cause fluctuations in RPM and CFM, reducing performance. During inspections, look for signs of wear or damage that might impair function. If you notice any worn or damaged parts, replace them promptly to prevent further issues. Calibration is essential to maintain precise airflow and speed control, so use the right tools to set components back to manufacturer specifications. Additionally, understanding Kia Tuning options can help you optimize your system for better performance. Consistent attention to alignment and timely parts replacement keeps your system running smoothly, prolongs its lifespan, and secures optimal performance for RPM and CFM balance.

Lubrication and Wear Management

Proper lubrication is essential for minimizing friction and preventing excessive wear on your airflow system’s moving parts. Using the right lubrication techniques ensures that components operate smoothly and reduces the risk of damage. Regularly applying the appropriate lubricants at recommended intervals helps maintain peak performance and extends equipment lifespan. Pay close attention to wear indicators such as unusual vibrations, noise, or temperature increases, which may signal insufficient lubrication or component deterioration. Consistently inspecting lubrication points and replacing worn-out lubricants prevent friction buildup and wear. Keep detailed records of lubrication schedules and wear signs to identify patterns and adjust your maintenance routine accordingly. Effective wear management through proper lubrication techniques ultimately keeps your system running efficiently, reducing downtime and costly repairs. Additionally, understanding the importance of maintenance schedules can significantly influence the longevity and efficiency of your equipment.

Monitoring System Performance and Data Analysis

You need to track system performance in real time to catch issues early and keep everything running smoothly. Analyzing this data helps you identify patterns and optimize settings for better efficiency. By focusing on data-driven insights, you can make informed decisions that improve maintenance routines and system longevity. Incorporating regular monitoring of sleep and mental health can also enhance overall system resilience and well-being.

Real-time Performance Tracking

To effectively monitor system performance, real-time data tracking plays a crucial role in identifying issues before they escalate. It allows you to catch problems early, minimizing downtime and maintaining peak RPM and CFM. Use sensors to monitor key indicators like air filter cleanliness and vibration analysis, which reveal mechanical imbalances or blockages. Regularly review this data to spot trends and anomalies. Additionally, paying attention to indoor air quality metrics can help you assess overall system effectiveness and ensure a healthier environment. This proactive approach helps you make informed maintenance decisions, ensuring your system runs smoothly and efficiently.

Data-Driven Optimization

Harnessing data-driven insights is essential for optimizing system performance, as it enables precise monitoring and informed decision-making. By analyzing vibration data, you can detect early signs of imbalance or misalignment, preventing costly failures. Regular vibration analysis helps identify patterns that signal when components need replacement, ensuring your system runs smoothly. With accurate data, you make targeted adjustments, avoiding unnecessary part replacements and downtime. This approach also allows you to track performance trends over time, refining your maintenance schedule for maximum efficiency. Embracing data-driven optimization means you rely less on guesswork and more on actionable insights, leading to improved system reliability and longevity. Ultimately, integrating vibration analysis and data analysis into your routine ensures your RPM and CFM are consistently optimized.

Implementing Preventive Maintenance Strategies

Implementing preventive maintenance strategies is essential for guaranteeing the longevity and efficiency of your equipment. To succeed, focus on proper maintenance scheduling to avoid unexpected breakdowns. Regularly check sensor accuracy to maintain precise readings, which are critical for ideal RPM and CFM balance. By planning routine inspections and servicing, you can catch issues early and reduce downtime. Additionally, monitoring Honda Tuning components can help optimize performance and prevent costly repairs.

Implementing routine maintenance and sensor calibration ensures reliable equipment performance and reduces costly downtime.

Consider these key actions:

- Schedule maintenance based on usage patterns and manufacturer recommendations

- Calibrate sensors regularly to ensure measurement accuracy

- Keep detailed records of all maintenance activities for future reference

This approach helps you stay ahead of potential problems, enhance performance, and extend the lifespan of your equipment. Preventive maintenance isn’t just a task; it’s a strategic tool for operational excellence.

Training Staff and Documenting Maintenance Procedures

Effective staff training and thorough documentation of maintenance procedures are essential for maintaining consistent equipment performance. Engaged employees understand the importance of proper maintenance and follow schedules diligently. Well-documented procedures ensure everyone is on the same page, reducing errors and downtime. To boost employee engagement, involve staff in creating and updating maintenance routines, making them accountable. Clear documentation supports maintenance scheduling, helping you plan inspections and repairs efficiently. Use the table below to visualize key ideas:

| Aspect | Benefit | |

|---|---|---|

| Staff Training | Improves skills, boosts engagement, ensures consistency | |

| Maintenance Documentation | Provides clear guidance, reduces mistakes, enhances accountability | |

| Maintenance Scheduling | Ensures timely upkeep, minimizes equipment downtime | The importance of understanding prophetic dreams can also highlight how interpretive clarity and consistent practices are crucial in various fields, including maintenance routines. |

Frequently Asked Questions

How Does Ambient Temperature Affect RPM and CFM Measurements?

Ambient temperature impacts your RPM and CFM measurements by affecting measurement accuracy. As temperature rises, air expands, causing fluctuations in airflow and potentially skewing readings. Cooler temperatures lead to denser air, which can increase measured airflow and RPM values. To guarantee precise measurements, you should account for temperature variations, use calibrated instruments, and consider temperature corrections. This way, you maintain reliable data regardless of environmental changes.

What Are the Common Signs Indicating Maintenance Is Needed?

Did you know that 60% of equipment failures are due to inadequate maintenance? If your system shows inconsistent RPM or CFM, it’s a sign you need to check your filter replacement schedule and lubrication routines. Listen for unusual noises, observe vibrations, or notice drops in performance. These signs indicate that your machinery needs attention to prevent costly breakdowns and guarantee ideal operation.

How Often Should Calibration Be Performed for Optimal Accuracy?

You should perform calibration regularly, ideally every 6 to 12 months, to guarantee measurement accuracy. Calibration frequency depends on your equipment’s usage, environment, and criticality of measurements. Frequent calibration helps detect and correct drift, maintaining precise RPM or CFM readings. Always follow manufacturer recommendations and keep records. Proper calibration ensures your tools deliver reliable data, preventing errors that could impact performance or safety.

Are There Specific Brands of Equipment Best Suited for Precise Control?

Think of choosing equipment like selecting a trusted partner; brand reliability matters. Brands like Fluke, Testo, and Extech are known for their precise control and compatibility with various systems. They offer high-quality, durable devices that help you maintain ideal RPM and CFM. Investing in reputable brands ensures consistent performance, reduces calibration frequency, and keeps your measurements accurate. Trust proven names to keep your operation running smoothly and precisely.

How Can Maintenance Routines Be Optimized for Energy Efficiency?

You can optimize your maintenance routines for energy efficiency by implementing regular maintenance scheduling, ensuring equipment operates at peak performance. Clean and replace filters, check for leaks, and calibrate controls routinely to minimize energy waste. Monitoring equipment performance helps you identify inefficiencies early. By maintaining your systems properly, you’ll achieve better energy savings, reduce operational costs, and extend equipment lifespan. Prioritize scheduled inspections and proactive adjustments to maximize efficiency.

Conclusion

By mastering the balance between RPM and CFM, you guarantee your system runs smoothly like a well-oiled machine. Regular checks and maintenance keep everything in sync, preventing costly breakdowns—just like the clockmakers of old who kept their gears turning flawlessly. Stay vigilant, document your routines, and train your team. With consistent effort, you’ll achieve ideal performance and longevity—because, in the end, maintenance is the secret to keeping your operation humming like a Swiss watch.